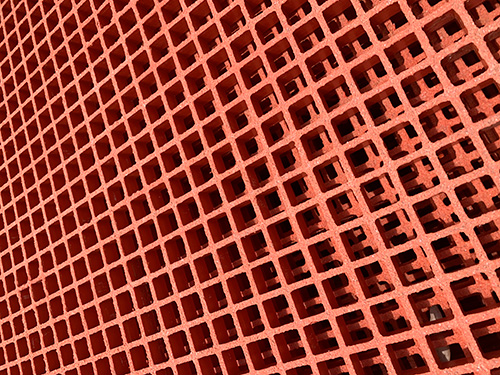

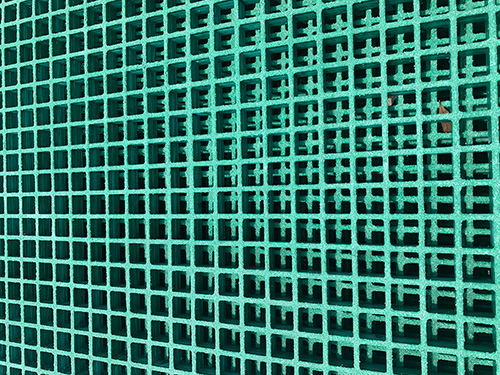

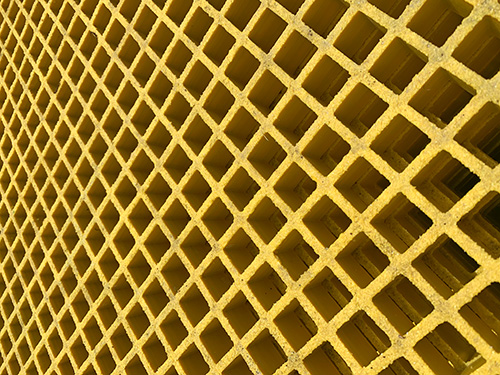

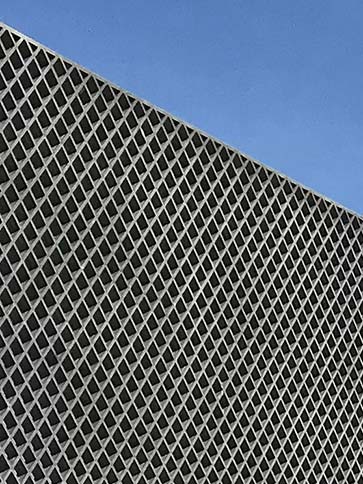

Fiber Reinforced Plastic or Fiberglass Reinforced Plastic (FRP) products are created using high-quality polymer and fibers that enhance the surface’s strength and durability. Since 1978, AMICO Seasafe® FRP products have been tested and proven in the harsh environment of the offshore Oil & Gas industry.

Our Fiber Reinforced Plastic (FRP) products provide the load capacity of steel, plus the inherent characteristics afforded by Pultrusion Technology: non-conductive, chemical resistance, non-magnetic, and corrosion-resistant. These characteristics reduce shock hazard and make our Fiber Reinforced Plastic (FRP) products transparent to radio waves, radar and microwaves.